Volvo Trucks investing in better times

“Starting up major building conversion projects in the midst of a recession is unusual but completely logical and correct,” says Johan Jinhage, Site Manager of Volvo Trucks Gothenburg Production. He’s a strong believer in preparing yourself for the future and benefiting from the low rates of production and surplus capacity prevalent in recessions. And he has technical project managers from Coor to help him.

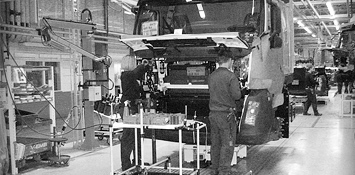

Volvo has a global concept for the factories of the future, and within the auspices of this concept, Johan has been responsible for extensive adaptation of Volvo Trucks’ major plant at Tuve, in the midst of the recession.

The project is called FFT (Future Factory Tuve) and basically means installing two driven lines (according to the conveyer belt principle) in the plant. Driven lines are used at many high-volume production plants round the world at present, and contribute to an efficient assembly process. Several modifications of production premises have been necessary in tandem with installation processes.

Use the recession to prepare for the upturn

Starting rebuilds in the midst of an economic crisis is unusual, but simultaneously completely logical and correct according to Johan.

Starting rebuilds in the midst of an economic crisis is unusual, but simultaneously completely logical and correct according to Johan.

“The new installation involved a lot of work in our assembly hall, and when we’re at low volume, we’ve got good prospects of closing down one line at a time without our deliveries being affected. Meanwhile, we can use our own people for some of the work to minimise our project costs. By accelerating this installation project in the recession, we’re preparing for the future, when hopefully, volumes have returned,” he adds.

Committed support from Coor – right through the process

To help them, Volvo Trucks appointed Coor’s Technical Project Managers. Anna Frohlund, a Group Manager at Coor, tells us about the work she did:

“We were involved right through the project – from the feasibility study when the concept was prepared, to work on implementing and commissioning installations. We were also responsible for adapting premises around the installations. Work went on for an extended period but intensified in 2009, when at its peak, there were eight Coor people involved on the project, says Anna.

Both parties are very satisfied with their close collaboration and its results. The project set major challenges and high demands on co-ordination while production continued.

“With its competence and experience of industrial projects, Coor delivered continuous project management that satisfied our standards well,” notes Johan.

Anna is impressed by how Volvo Trucks used the recession to prepare for an upturn.

“Their thinking was absolutely right. In manufacturing it’s hard to manage wide demand fluctuations. In an upturn, production capacity needs to be maximise. Volvo Trucks has used the recession to increase its production capacity in a segment it really believes in. It’s intelligent, courageous and strong,” adds Anna.

Cautious optimism

At its Tuve plant, Volvo is well-equipped for the turnaround, and is also starting to see signs of things brightening up. Order bookings to the plant have increased and Volvo Trucks is now reinstating staff it laid off after a difficult time downsizing and running production on tickover.

“We’re feeling cautious optimism, and now that order bookings are increasing, we’re getting our second new flow going. Hopefully, we’ll benefit from all the capacity we’ve got at Tuve now. I’m looking forward to it,” says Johan in conclusion.

Want to find out more?

Get in touch with Anna Frohlund.